LUOYANG BOBI BEARING (trademark: NERT), a leading manufacturer of high-precision thin-section bearings in China, was established in 2010 and is located in Luoyang City, Henan Province. For over 14 years (since 2010), we have specialized in the production, research, and development of bearings, focusing on creating “high-tech, high-precision, advanced, customized” bearing solutions.

Our facilities occupy 35,000 sq.m., featuring 20,000 sq.m. of building area, which includes:

3,000 sq m. of office space

500 sq.m., dedicated to our R&D center

2,000 sq.m, for the international marketing & reception center

Our mission is to provide customers with comprehensive solutions that encompass design, development, manufacturing, testing, evaluation, and exceptional after-sales service. The factory is situated in the Ximagou Section, Sanxi Road, Luoyang City, Henan Province.

Specializes in manufacturing high-precision bearings and components, including: thin-section ball bearings, precision ball bearings, specialized high-precision bearings, crossed roller bearings, harmonic drive bearings, cylindrical roller bearings, and custom-engineered bearings.

Our ball bearing designs feature radial contact, deep contact, 4-point contact, and angular contact configurations, compliant with ISO tolerance classes P6 (ABEC-3), P5 (ABEC-5), and P4 (ABEC-7).

We produce bearings with inner diameters ranging from 3.5 mm to 1500 mm, and widths spanning 2.5 mm to 25.4 mm.

These precision components are critical to industrial applications such as CNC machine tools, precision measurement instruments, semiconductor lithography systems, wafer handling equipment, textile machinery, paper mills, robotics, wind energy systems, MRI devices, UAVs, air compressors, tension levelers, radar systems, missile tracking cameras, and aerospace technologies.

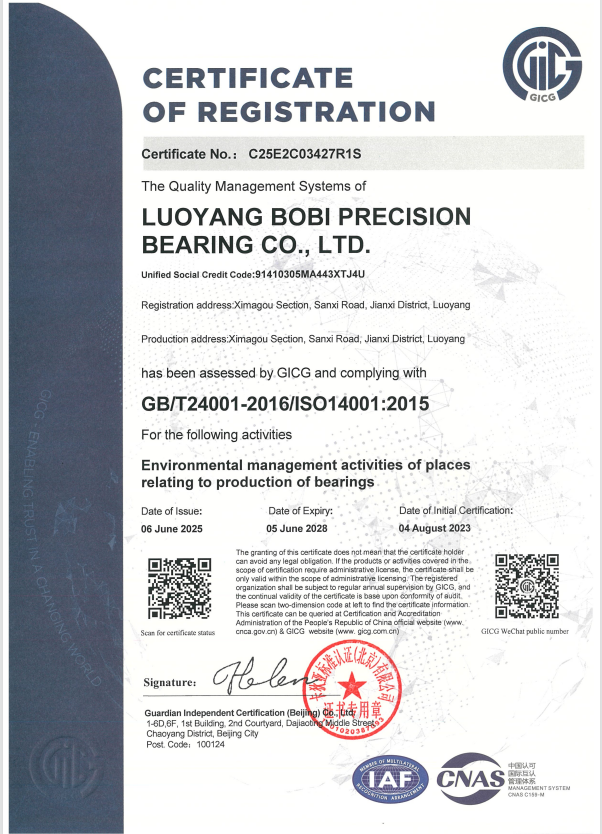

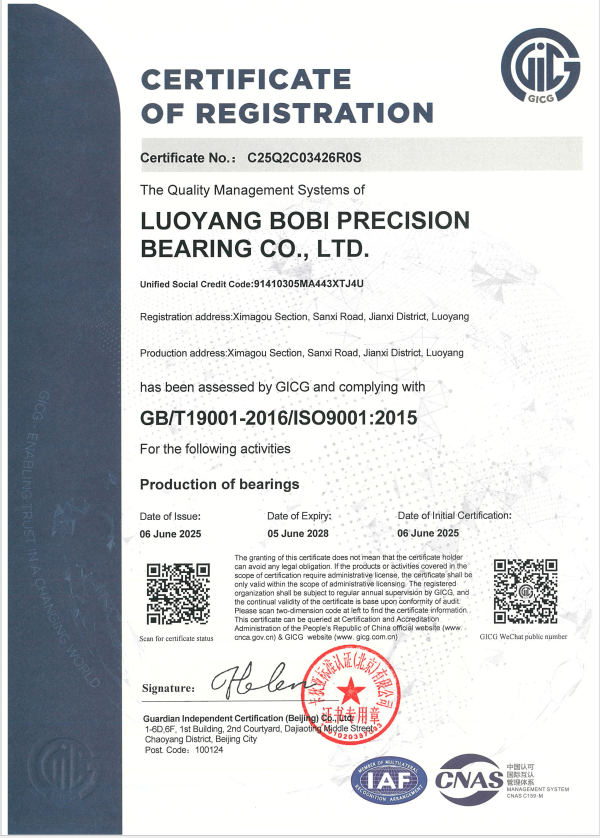

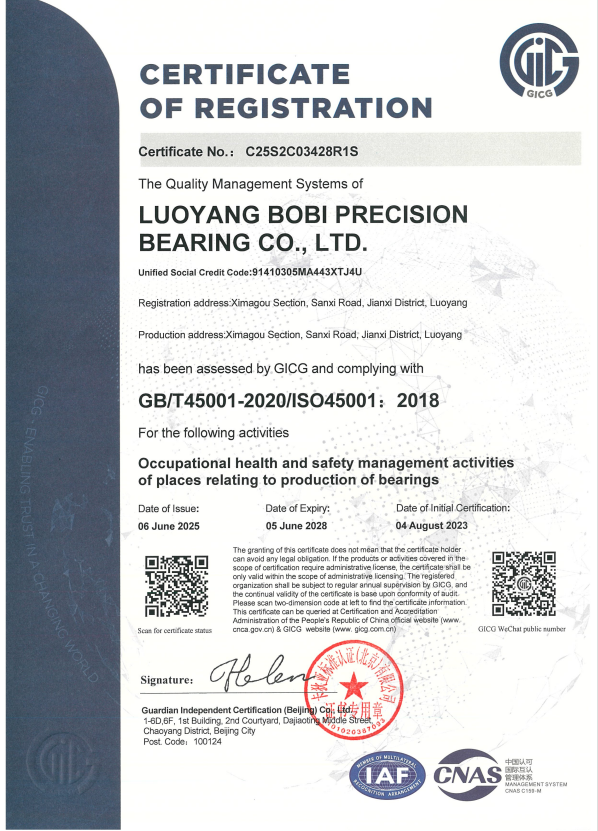

Certified to ISO 9001, we implement a robust quality control system that encompasses first-article inspection, in-process checks during production, and final testing before delivery, ensuring the consistent delivery of high-quality products. A dedicated bearing testing laboratory, located adjacent to production lines, verifies component compliance before advancing to subsequent processes.

Our facility operates 8 production lines outfitted with advanced machinery, including CNC lathes, machining centers, CNC grinding machines, and ultra-precision equipment. Supported by 50 skilled personnel—3 technical engineers and 5 inspectors, most with over 15 years of bearing manufacturing expertise—we combine cutting-edge production tools with rigorous testing protocols to ensure product precision and reliability.

Our R&D department efficiently translates customer design requirements into custom-bearing solutions, while our non-standard bearing customization services further enhance flexibility to meet specialized needs.